All about the selection of grain storage silos: a guide from FARMIX, Volume 1.

Are you planning to buy new grain storage silos and need advice on their selection? Do you want to be sure that they will last for many years and be truly reliable? There are several key factors to make the right decision. FARMIX can help you with this.

Welcome to our new series of articles that will guide you through the process of choosing a safe and quality grain storage silo. In the coming weeks, we’ll look at the key factors you should consider when choosing a new storage silo. From determining capacity and material selection, to assessing the quality of construction, to the importance of design and ergonomics. We’ll also look at safety features and the importance of choosing the right supplier. Our goal is to provide you with a comprehensive guide to help you make the right decision and select a storage silo that is not only safe and high quality, but also efficient and reliable in the long term.

FARMIX, your reliable partner for storage solutions and post-harvest lines

First, a little about us so you can see that you can turn to us for the best solution. FARMIX is an expert in designing smart storage solutions for farmers and large agricultural businesses. We specialise in the design and construction of new post-harvest lines and the refurbishment of existing ones. We offer quality grain storage silos with the highest quality and safety standards.

And now the promised aspects in the selection of new grain storage silos:

Determination of grain storage capacity: How to do it?

The first step is to determine the storage capacity to fully meet your needs. This includes the acreage of your farm and the volume of grain you plan to store. You also need to take into account the climatic conditions and other factors that may affect grain storage, such as humidity, temperature and ventilation. Focus on the materials used for the construction of the storage silos. Choose those that are able to withstand the weather and prevent harmful effects of insects and rodents.

Increasing the lifetime of grain storage silos with galvanised sheets

Galvanised sheet metal has become the industry standard for grain storage silos. Its proven durability, cost-effectiveness and low maintenance make it ideal for agricultural professionals. In addition, galvanised sheet metal used in silos is easily recyclable, making it environmentally friendly. Galvanizing is a key component in the manufacture of grain storage silos. It involves coating steel or iron with a layer of zinc to create a corrosion resistant barrier. This protection is particularly beneficial for grain storage silos that are constantly exposed to the elements. Galvanised sheet metal will significantly extend their life and reduce maintenance costs. The galvanizing process is efficient and cost-effective. It involves immersing steel or iron sheets in a bath of molten zinc, which chemically bonds with the surface. This protective coating is flexible and self-healing, so that even in the event of scratches or damage, the zinc coating continues to protect the underlying metal. Most storage force suppliers offer a standard 350 gsm galvanizing. However, it is a very wise investment to choose galvanizing above 350 g/m². Extended silo life means less frequent replacements, reducing raw material requirements and energy consumption in production. This helps to reduce the environmental impact in line with the growing demand for environmentally friendly farming practices. Leading storage silo suppliers such as FARMIX have recognised the potential of higher gsm galvanising and now offer 600 gsm galvanised silos as standard. By choosing these suppliers, agricultural professionals can enjoy the long-term benefits of increased durability and superior crop protection. Keep in mind that quality silo galvanizing is a critical factor in the long-term protection and preservation of the quality of stored crops. That’s why at FARMIX we supply silos with high quality galvanizing as standard. This is one of the advantages that will show in the long run – it saves costs for renovation and repair of storage capacities.

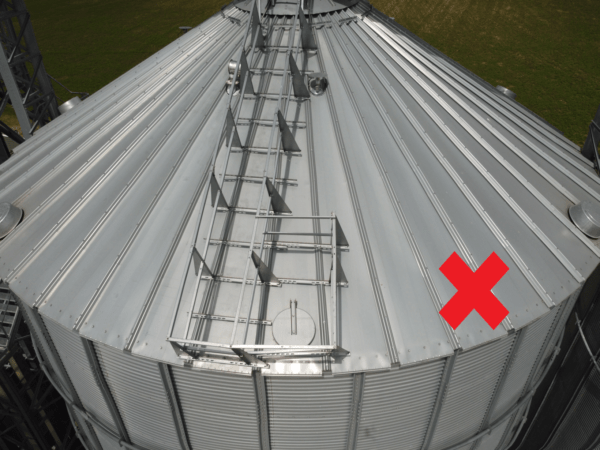

Roof staircase

Grain storage silos are large and tall structures that require regular inspection and maintenance. Traditional roof ladders can be a risky solution due to their lack of stability and support. Roof ladders with handrails offer a much safer alternative. They are made of durable materials such as galvanized steel or aluminum, so they can withstand harsh weather conditions and provide long-lasting performance. One of the biggest advantages of a roof staircase with handrail for grain storage silos is the higher level of safety. The handrail offers workers a secure grip when exiting, so it greatly reduces the risk of falls and accidents. In addition, these stairs are often equipped with non-slip treads, further increasing their safety profile. These essential structures are designed to provide easy and safe access to the top of the silo and allow for trouble-free maintenance, inspection and monitoring of the grain storage system. The roof staircase with handrail provides a safe solution for workers to carry out tasks without risk of injury. Worker safety is a priority for FARMIX and a staircase with a fixed handrail is the best way to prevent accidents and injuries. We dare say that roof stairs with handrails are an essential investment for any grain storage silo. They provide a safe and secure means of accessing the top of the silo for easy regular maintenance and inspection. Invest in roof steps with handrails. This will optimize the safety and efficiency of your grain storage operations. We recommend supplementing your silos with a quality staircase with a sturdy handrail. The other good news is that the price difference compared to conventional roof ladders is small and you will be able to sleep soundly.

Side door

One of the key elements of a grain storage silo that is often overlooked is the size and functionality of its side doors. Sufficiently large side doors allow easy access to the stored grain, but also to the just emptied silo for inspection, cleaning and maintenance. It is important to clean the silo floor after each grain removal. Without properly sized side doors, entering the silo and performing these tasks can be difficult and lead to potential safety hazards and reduced efficiency. We recommend installing a larger door for easy access to the silo. At FARMIX, we offer doors that are so-called “over two rings” or two sheets in height. This will make cleaning and maintenance in the silo easier – post-harvest line operators will be delighted. For the farmer or grain store operator, a well-functioning and properly designed grain storage silo is essential to ensure the quality of the harvested grain. Sufficiently large side doors are an essential part of a good silo.

Grain silo roof structure

The roof structure of the grain silo ensures efficient storage and protection of valuable grain. It is designed to withstand adverse weather conditions, allow proper ventilation of the grain and prevent deterioration. The ideal grain silo roof structure is durable, flexible and cost-effective. Galvanised steel, aluminium and stainless steel are often used for grain silo roof construction. These materials provide optimum strength and corrosion resistance, ensuring a long service life. The incorporation of ventilation systems, temperature control elements and advanced sealing technologies further enhance the performance and functionality of the grain silo roof structure. By investing in the right roof structure, you can minimize grain loss and maximize your return on investment. Looking for a reliable and durable solution that will ensure the quality and safety of stored grain over the long term? A quality steel roof truss may be the best choice. Its sturdy construction provides strong and stable support for the roof, so it will remain strong and withstand the elements.

Don’t miss the next part of our guide to choosing a safe and quality grain silo! In this installment, we’ll look at the importance of an all-weather floor and why it’s a better choice than aeration channels in concrete. Why it’s so important to pay attention to prov exhaust fans and what role do they play in maintaining the quality and longevity of stored commodities? Join us to find out how to choose the best one for your grain. Choosing the right silo can be challenging, but with our guide, you’ll become an expert .

Selecting grain storage silos: the FARMIX guide, Volume 2.

Selecting grain storage silos: the FARMIX guide, Volume 3.